|

Software Tools

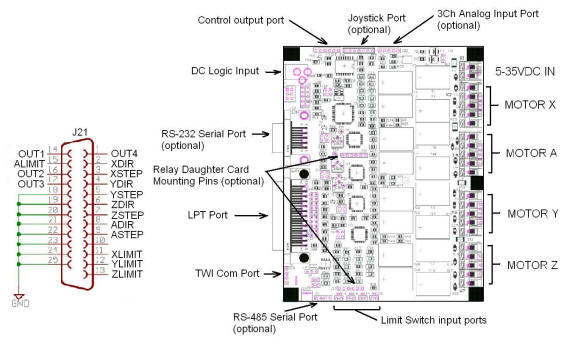

The MC433

is designed to work with a variety of third party G Code software programs.

Step input for each axis requires an active high pulse lasting at least

2useconds – step inputs are edge triggered. A high level on the Direction

input will turn the stepper clockwise or counterclockwise depending on how

the motor is connected to the drive port. The direction signal is sampled

after the step trigger so it must remain stable for at least 10useconds

after the step trigger.

Control Processor Reprogramming

The

Software in each

Motor Control Processor can be user upgraded the next software release using

a free desktop programming utility MC433Prog.exe. MC433Prog.exe can be

downloaded from the download tab.

Expansion Options

The

MC433 has

several expansion options: Relay Adapters, Joysticks, DRO and USB

Communication Controllers.

Three Relay adapters are available

- each controlled by the Auxiliary output lines. A low current DC relay

array capable of handling 24VDC at 2A or 120VAC at 0.4A , a high

current relay array capable of handling 30VDC at 4A or 120VAC at 2A

and a hybrid MOSFET controller that can be configured to control three small

stepper motors or operate as 12 independent 2A 30V switches.

|